A kinder version of denim.

CONTACT US

SUBSCRIBE

At Soorty, we see climate action as a shared responsibility to our planet and our partners. Every step we take – from replacing coal and improving energy efficiency to rethinking how our products are made and moved – is aimed at reducing our footprint while creating better value for everyone in our supply chain. This page is where we share the actions, innovations, and collaborations that drive our decarbonisation journey.

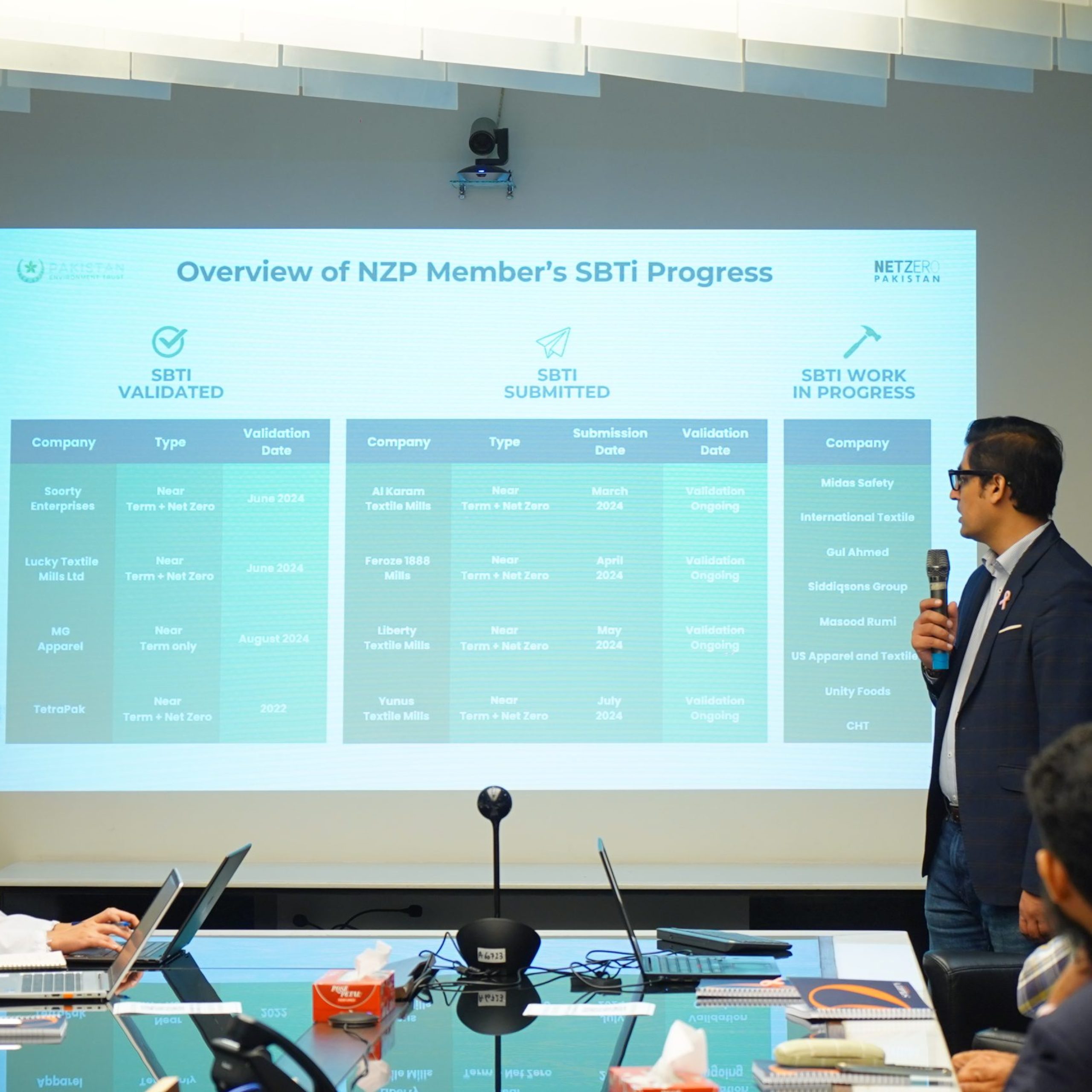

In April 2024, Soorty became the first textile manufacturer and supplier to international brands from Pakistan to have its Near Term and Net Zero targets validated by the Science Based Targets initiative (SBTi). These targets, developed after completing our full greenhouse gas (GHG) inventory in line with the GHG Protocol, commit us to reducing absolute Scope 1, 2, and 3 emissions by 54.6% by 2033 from a 2021 base year, and by 90% by 2050. The remaining 10% will be neutralised through high-quality carbon removals to achieve net zero.

Our targets cover our entire value chain – from the energy used in our operations to the materials we source and the transportation of our products. By setting these goals under the SBTi Net Zero Standard, we are aligning with the most rigorous, globally recognised framework for climate ambition in business.

Transitioning to renewable energy is one of the most direct and lasting ways to reduce our operational emissions. At Soorty, we have deployed 11.2 MW of on-site solar capacity across our group, generating clean electricity that directly replaces grid power from fossil fuel sources. This investment cuts Scope 2 emissions while reducing our exposure to energy cost volatility, ensuring stable and responsible production for our customers.

Our phased solar expansion plan aims to increase total capacity to 15 MW in the next two years, further strengthening our commitment to renewable energy and long-term climate resilience.

Wind energy plays a vital role in diversifying our renewable energy mix. At Soorty’s Nooriabad Spinning and Fabric Mill, we operate a 4.8 MW on-site wind turbine that supplies clean electricity directly to our production processes. By tapping into this abundant, zero-emission resource, we further reduce our reliance on fossil fuels and strengthen our progress toward decarbonising operations.

Beyond our factory boundaries, Soorty invests in large-scale renewable infrastructure through NASDA Green Energy – our sister concern operating a 50 MW wind farm in Jhimpir, one of Pakistan’s most resource-rich and strategically important wind corridors. While this facility is not physically connected to our manufacturing sites, it contributes clean power to the national grid, supporting Pakistan’s renewable energy transition and helping to displace fossil fuel-based electricity at a larger scale.

Our involvement in projects like NASDA Green Energy reflects a broader commitment to accelerating renewable adoption not only for our own operations but also for the communities and markets we are part of.

Phasing out coal is a cornerstone of our decarbonisation strategy. Across our operations, we have already achieved an 85% transition away from coal by replacing it with cleaner, renewable alternatives for our thermal energy needs. We remain committed to eliminating coal entirely from our operations as we advance toward our net-zero goals.

A major enabler of this shift is our adoption of biomass, sourced from agricultural and organic waste. In Sindh, where no formal biomass supply chain previously existed, we built one from the ground up – ensuring consistent quality, reliable sourcing, and traceability. By converting local waste streams into low-carbon fuel, we not only cut direct greenhouse gas emissions but also create new economic opportunities in rural communities.

This transition significantly reduces our dependence on fossil fuels, supports regional circularity, and aligns our manufacturing processes with the broader global shift toward net-zero production.

Soorty continues to invest in smart infrastructure upgrades that lower electricity demand and improve operational efficiency across our facilities. These measures directly reduce Scope 2 emissions and create a more sustainable baseline for future growth.

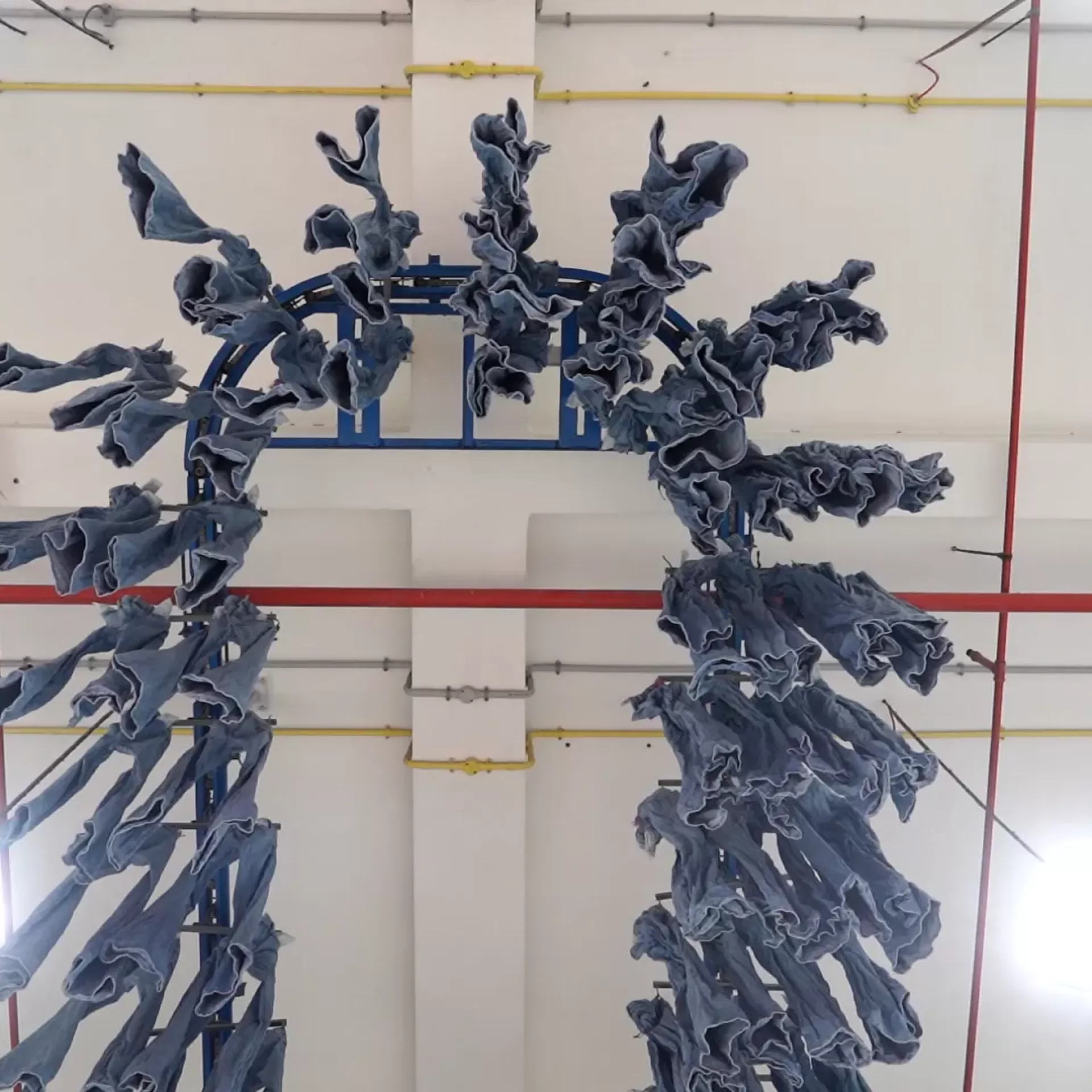

Our approach to decarbonisation goes beyond infrastructure – it’s embedded in how we design, dye, wash, and sew. By investing in advanced machinery and retrofitting existing equipment, we improve energy performance while maintaining product quality.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.