Driving positive change by promoting transparency, data-driven approaches, and honesty. We believe a transparent supply chain for a fashion industry that is genuinely fair, benefiting both the people and planet is absolutely necessary.

By being open about our sourcing, production, and impact data we aim to not only empower informed decision-making for our stakeholders, but also share our dedication to continuous improvement and innovation.

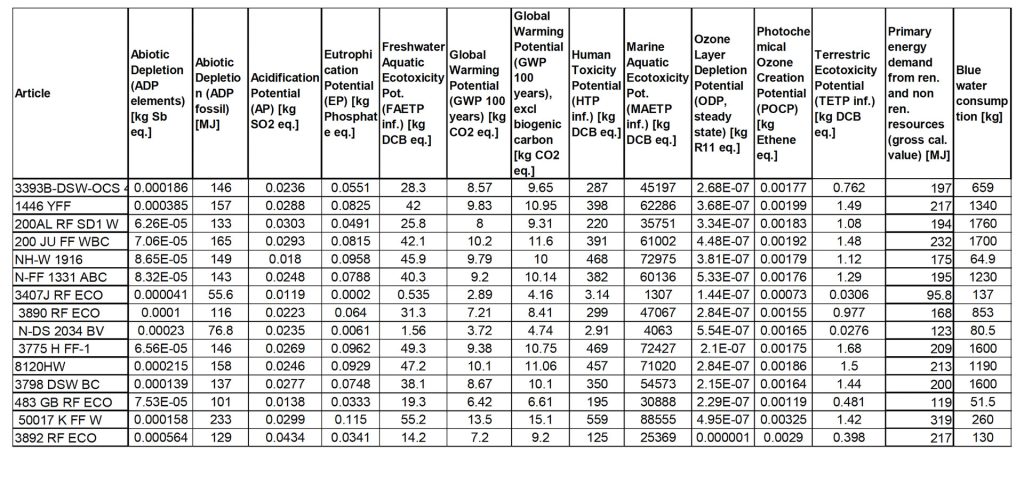

LIFE CYCLE ANALYSIS (LCA)

We did a Life Cycle Impact Assessment under the ISO 10440 and 14044 Guidelines of 15 products in order to have transparent, product level impact data. The summary is below.

Moving forward, we’re working on a product level carbon footprint calculator.

TRACING & AUTHENTICATING PRODUCTS

At Soorty, our unwavering commitment to sustainability drives us to perpetually refine our processes. Our long-standing partnership with Haelixa elevates our dedication to work towards an accountable, trustable and reliable fashion ecosystem.

Using the pioneering DNA traceability solution, we’re able to physically mark, trace, and authenticate Soorty products (in fiber or garment form), ushering in a new era of transparency.

THE FACTORY OF THE FUTURE, IN NUMBERS

Soorty’s Unit 5/6, our future-proof, LEED Platinum Certified factory merges creativity and design for purpose in the world’s most responsible denim production facility at scale.

Energy Efficiency

Energy efficiency is among our priority areas of measure in our sustainability journey. As a future proof factory, Soorty’s Unit 5/6 is equipped with the latest technology set up which reduces energy use radically while replacing fuel sources with renewable ones.

The responsible innovations and investments which helped us save energy are:

Solar panel rooftop that powers our sewing floor,

An Air Conditioning Unit that runs on the excess heat of our generators, requiring no new energy,

100% LED lighting,

Air compressors utilizing variable frequency drive motors,

Moving conveyors that use only the atmospheric heat to dry jeans.

In addition, our facility uses no cables, only busway systems.

-

carbon emission

reduced -

solar energy produced

-

equivalent of

trees planted

Factory Efficiency

jeans

per day

Design for purpose, and a responsible mind-set that reduces the use of limited resources as well as our footprint on them has helped us increase our efficiency. Some examples are:

The best way to reduce materials’ waste is to use less from the beginning and utilize design as a tool of improvement.

Value engineering and DESIGN FOR MANUFACTURABILTY drastically improve yield.

We collect & repurpose our own waste, scraps and factory returns. When the recycled material cannot be used, we control the supply chain to find those who can, in an effort to approach waste as a resource.

Creative and an open mind helps to optimize processes while using available materials.

Reusing inputs again and again instead of discarding them reduces new raw material.

-

time required to produce

1 jean conventionally -

time required to produce

1 jean in Denim Kind

Water Efficiency

Water for Humanity is our proprietary internal water management system that helps us reduce our fresh water need and save water via:

Collecting the rainwater,

Recycling and reusing our process water in a fully automated technology,

Production with re-circulating washing machines

Implementing smart, responsible technologies that require less water compared to conventional methods like mist, foam and ozone gas application,

Using water efficient spray faucets and water efficient flush tanks.

-

people's daily

water need -

water saved

this month -

waste water

recycled and reused

CERTIFICATIONS